In the world of engineering, mechanics, and manufacturing, precision plays a pivotal role in ensuring the quality and accuracy of components. One of the fundamental tools used for measuring small distances and dimensions with high precision is the screw gauge. This device, also known as a micrometer screw gauge, provides accurate measurements to the nearest hundredth of a millimeter, far surpassing the capabilities of a standard ruler or caliper.

What is a Screw Gauge?

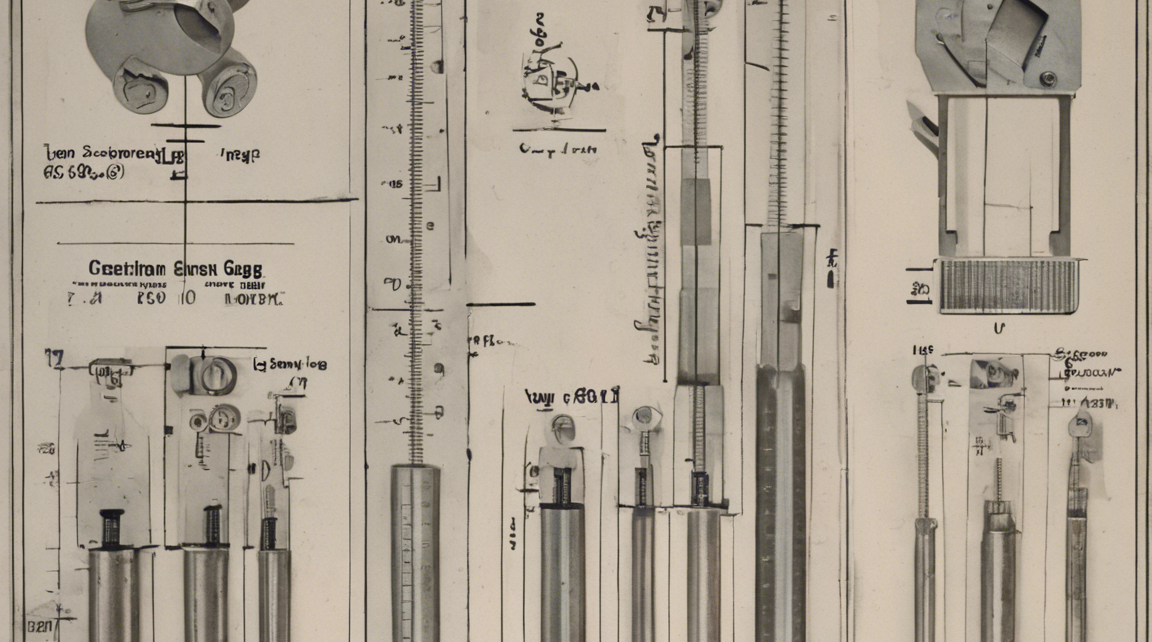

A screw gauge is a precision instrument used for measuring small distances with high accuracy. It consists of a calibrated screw mechanism that is fitted into a calibrated sleeve. The sleeve has markings which allow the user to read the measurement directly. The screw gauge typically has a thimble and a ratchet stop to ensure consistent measurement pressure and prevent overtightening.

Parts of a Screw Gauge

- Frame: The main body of the screw gauge that houses all the components.

- Sleeve: The stationary outer part of the screw gauge with calibrated markings.

- Thimble: The rotating part of the screw gauge connected to the screw mechanism.

- Ratchet Stop: A mechanism to ensure uniform pressure while taking measurements.

How Does a Screw Gauge Work?

The working principle of a screw gauge is based on the lead screw mechanism. When the thimble is turned, it moves along the screw, causing the spindle to move forward or backward depending on the direction of rotation. This movement is transferred to the anvil, which then contacts the object being measured. By reading the position of the thimble on the sleeve, the user can determine the precise measurement.

Reading a Screw Gauge

To read a screw gauge measurement accurately, follow these steps:

- Close the jaws gently around the object to be measured.

- Use the ratchet stop to apply slight pressure on the object.

- Note the position of the thimble on the sleeve.

- Read the main scale reading and the circular scale reading.

- Add both readings together to get the final measurement.

Advantages of Screw Gauge Measurement

Using a screw gauge offers several advantages, including:

- High precision: Screw gauges provide measurements up to 0.01 mm, ensuring accuracy in small-scale measurements.

- Consistency: The ratchet stop mechanism helps maintain consistent pressure for reliable results.

- Versatility: Screw gauges can measure various objects, including spheres, cylinders, and cubes.

- Durability: Made of hardened steel, screw gauges are robust and long-lasting.

Common Applications of Screw Gauges

Screw gauges find widespread use in industries such as engineering, manufacturing, metrology, and quality control. Some common applications include:

- Component Measurement: Checking dimensions of machine parts and components.

- Quality Assurance: Verifying the precision and accuracy of manufactured items.

- Research and Development: Conducting experiments that require precise measurements.

- Educational Purposes: Teaching students about precision measuring techniques.

Maintaining a Screw Gauge

To ensure the accuracy and longevity of a screw gauge, it is essential to follow these maintenance tips:

- Keep it clean: Regularly clean the measuring faces and spindle to remove dirt and debris.

- Avoid over-tightening: Use the ratchet stop to apply consistent but gentle pressure while measuring.

- Store properly: Keep the screw gauge in a protective case or box when not in use.

- Calibrate regularly: Periodically check and calibrate the screw gauge to maintain accuracy.

Frequently Asked Questions (FAQs)

- Can a screw gauge measure both internal and external dimensions?

-

Yes, a screw gauge can measure both internal (using the anvils) and external (using the spindle) dimensions accurately.

-

What is the least count of a screw gauge?

-

The least count of a screw gauge is typically 0.01 mm, meaning it can measure up to the nearest hundredth of a millimeter.

-

How accurate are screw gauges compared to other measuring instruments?

-

Screw gauges are more accurate than standard rulers and calipers, making them ideal for precise measurements in engineering and manufacturing.

-

Can a screw gauge be used for measuring angles or depths?

-

No, screw gauges are designed specifically for linear measurements and cannot be used for measuring angles or depths.

-

What materials are screw gauges typically made from?

- Screw gauges are commonly made from hardened steel to ensure durability and accuracy in measurements.

Understanding the screw gauge measurement system is essential for professionals working in fields where precision measurements are critical. By mastering the use of this precision instrument and following best practices for maintenance, users can ensure accurate and reliable measurements for their various applications.